Wide Range

Laser modules have a lifetime of more than 100,000 hours. They can be used to engrave with repeatable precision of +0.00039".

The software interface can be accessed by typing in your machine's IP address on the browser's address bar.

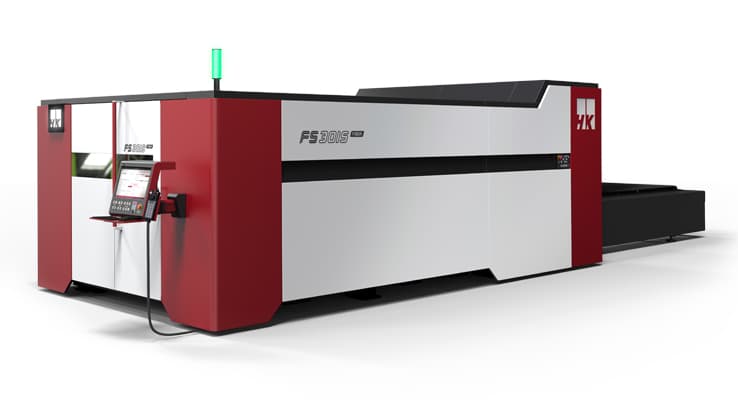

ST-FC3015L is a heavy duty industrial flatbed fiber laser cutting system for sheet metal fabrication of stainless steel, mild steel, titanium, aluminium with different laser powers, such as 1000W, 1500W, 2000W and 3000W in commercial use, the laser source can be Chinese Raycus, Germany Precitec or Germany IPG brand. More than 3000W laser power, we have more industrial sheet metal laser cutters for choose.

FSLmuse Pandora requires 254mm lens, 330mm lens, and 420mm lens to work in open settings. Only then the laser can effectively focus on the material.

F-theta(?) is the laser module's electromagnetic radiation. The laser module uses an F-theta(?) lens that has high energy uniformity, narrow focus spots, and low attenuation.

Plasma can, however, cut any type or metal up 80mm thick or 3 inches thick. Plasma can start cutting quicker than laser when cutting thicker material.

Laser modules have a lifetime of more than 100,000 hours. They can be used to engrave with repeatable precision of +0.00039".

The software interface can be accessed by typing in your machine's IP address on the browser's address bar.

Raycus 50W fiber-laser can mark or etch in aluminum at a angle of 90� using 100% of its laser power.

EZCAD 2.0, a free program that is compatible with Microsoft Windows XP/Windows 2000 and Windows 7, WIN8, WIN 10, OS.

Even though fiber lasers are solid-state lasers, fiber lasers are different from diode lasers and there is a significant difference in their capabilities.

Gulf States Saw & Machine Co., newest laser machine combines our top-of-the-line technology and our latest features in a compact desktop format, with a 30-watt fiber option for marking metals and engineered plastics.

Triumph Laser supplies EZCAD2.0 software to control their desktop laser engraver. EZCAD2.0 is capable of creating basic shapes as well as text.

Laser energy delivered to the spot is increased if the M2 value gets closer to 1 than it is. It is able to process thicker materials using shallow wells.

Gulf States Saw & Machine Co. will provide a warranty of 2 years on all their fiber-laser machines. Amazon will provide a 30-day guarantee for any replacement parts.

How plasma works can get a little complicated. So, I�m explain as simply and quickly as possible. Plasma cutters basically heat up gas so much that it gets hot enough to melt metal. Then, when the metal is heated up enough to melt, it is blown away with gas to make the cut. There�s a complicated science behind this, but I�ll save that for another day! (or you can research on your own if you like).

In fact, the diode module in a fiber laser typically outlasts other technologies by three times. Most lasers have a lifespan of about 30,000 hours, which equates to about 15 years of use. Fiber lasers have an expected life of 100,000 hours, which equates to 45 years of use.

Fiber lasers leave unsightly marks on wood.

The goal of any marking or engraving project is to create a readable mark, whether by hand or machine. Uncontrolled absorption, on the other hand, results in an uncontrolled mark on the wood.

Laser cutters cost between $13 and $20 per hour to operate. Water jet cutters cost between $15 and $30 per hour. Overall, the operating costs are comparable, and the total cost will be determined by your project.